SCREEN PRITNING

Screen printing is the go-to print method for many reasons. It’s affordable and in most cases, will last the life of the apparel product.

It’s most advantageous when printing a simple, single spot colour design on a large amount of t-shirts. Screen printing works on all types of apparel materials including cotton and poly blends. The colour is more vibrant than other print methods but it can feel heavy on the material.

Four Color Process

This is the oldest form of decorating apparel using a similar method as an ink jet printer by blending the four process colours of Cyan, Magenta, Yellow, and Black to create the full spectrum of colours. Four colour process printing works best on white or light coloured garments.

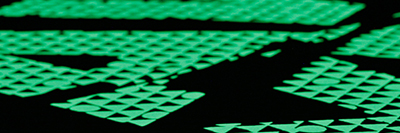

Glow-in-the-Dark Printing

The go to method for speciality low light graphic impact on apparel for glow runs or other night time events. Glow-in-the-dark inks must be exposed to a light source to charge the glow-in-the-dark ink. Longer exposure to light will brighten and extend the life of the glow effect.

Metallic Ink Prints

Metallic ink printing offers an eye catching effect for custom designs on t-shirts and other apparel. Choose from shimmer and regular metallic for different looks.

Puffy Prints

Puffy printing offers a retro puffed up look to any custom design on apparel. An additive is mixed in with the ink which is activated when heat is applied.

DYE SUBLIMATION

Dye sublimation printing is a digital printing technology, which reproduces colourful images on multiple items, like clothing and novelties. The colour limitations and reproduction possibilities are endless when printing, but is limited to white or metallic substrates such as polyester t-shirts and clothing, mugs, plates and other items.

In the past, processes like screen-printing which required fairly involved and labour-intensive processes were not a cost effective solution in small quantities, as it requires more time for preparing the artwork and the equipment for the production process. Therefore, if you want to print only a small amount of T-Shirts, choosing screen-printing would be expensive.

On the other hand, dye-sublimation printing, is a quick and inexpensive process in both setup and production, which which requires far less time to setup, making it an ideal choice for creating personalised one-of-a-kind items, or for mass-producing a variety of custom products.

Dye-sublimation printing can also provide a beautiful and permanent colour that is embedded in the substrate or fabric, rather than printed on the surface. Embedding ink into the substrate prevent fading or cracks also after several times of washing.

HEAT TRANSFERS

We carry the entire variety of heat transfer materials to apply to almost any apparel! Whether you are wanting to create a personalised gift, adding a name or number to a jersey, or your business is looking for new eye catching apparel, Yarra Valley Printing are the clothing experts!

We also carry printable Siser Heat Transfer Vinyl as well as various colours in Siser Easyweed, Electic, Glitter, Glow in the Dark, and Sub Block.

Full Colour Digital Transfers

These are ideal for full colour image reproduction that can be applied to almost any type of material including performance wear, spandex, and even nylon. It is sometimes used to replace the embroidery method if the image contains a lot of fine detail. The images are adhered with the application of heat and pressure onto the garment.

Flock Printing

Flock printing is a digital cad cut vinyl that has the raised look but fluffy feel of a short wool print. The feel is like velvet and very soft to touch, but is extremely flexible and great to wear.

Electric

Electric is the film to go to when you want to give your design or logo that extra pop! The PS Electric range has a Pearlescent look with a pressure sensitive backing making it easy to cut and weed, it can also be used for multi-layered designs. Available in 22 dazzling colours

Foil

Foil is another product that has been recently added to the range. It has been hugely popular since it’s arrival, why? It gives off a similar look to a satin chrome, but has a much better life span than mirrored chrome films.

Glitter

Moda Glitter 2 comes in 51 dazzling colours, maximum sparkle without shedding any glitter flakes. Glitter 2 has a pressure sensitive backing, 325 microns thick and is recommended to use a 45°/60° blade. The White Glitter 2 can be Dye Sublimated onto directly.

Perforated

Perforated is a film that is perfect for sports uniform’s as it has 30% less coverage due to the perforated holes in the film. Available in 5 colours.